Cold welding for linoleum: characteristics, technology and instruction

Linoleum is a very common material, not losing popularity and now, when on the shelves with a rich choice of flooring - laminate, parquet, tiles and so on.

The Popularity of this material due to its advantages: durability (varies by class), resistance to moisture, ease of installation, and even some insulation.

A Significant disadvantage of the linoleum - joints. Well, when I can make room in one piece, but this is rare. In this case, it is necessary to connect the material, preferably so that the seam was not noticeable.

You Can press the edges of the joint with a metal nut, but in this case, there is formed the irregularity of the floor. In addition, the thresholds do not guarantee the integrity, and while, for example, wash the floor moisture can get into the seam.

It is Therefore much more widespread welding. There are two ways - hot and cold welding for linoleum.

Hot fusion

At the heart of this method lies in heating of the material. Hot welding is used mainly for coating high-strength linoleum production, commercial and other areas where the flooring is experiencing a high load. Another niche application of this method - very long seams.

The Hot welding is carried out using the special tool - burner, the heating temperature up to 400 OS. In the seam when it is inserted a special cord, which plays the role of "welding electrode". When melted, it connects the edge of the seam into a single structure. After cooling, remove the excess connecting material and the joint sanded. Welding cord structure is similar to the linoleum, so the seam is invisible.

Recommended

Staff evaluation: system and methods

Personnel Assessment allows you to identify how competent the employees involved in the enterprise, and it is the performance of their work – the most significant factor affecting the efficiency of the company. To clarify the impact of performa...

How to start your own business: important aspects.

Many people, tired of working for someone else, are increasingly thinking about how to start your own business. Someone wants to open a salon, someone store, and someone enough and vegetable stalls. Before you throw in the pool with his head, it is i...

Business activities. its essence and basic functions

The Entrepreneurial activity of the citizen – is undertaken at your own risk and independent activity, which aims to systematically profit through the sale of works, goods, services, use of the property. The citizen engaged in such activities, ...

The Hot welding has a number of disadvantages:

- The Work must be performed by professionals. For independent hot welding, for example, repair of apartments need to purchase special equipment. In addition to the burners, requires small scissors to trim the excess seam and nozzle for laying the welding cord. Moreover, some skill is necessary work. The first attempts are likely to be, unsuccessful, the material will be ruined, and the tools after completion of the work will lie idle.

- Method is only suitable for thick and hard linoleum - thin or not very good quality material will not withstand heat and will melt.

- If treated with a burner at independent welding there is a chance of injury.

The Method is not well suited for premises where the work volume is small, and repair many prefer to do it yourself.

Cold

This method is based on the use of special chemical composition. Cold welding - adhesive joints of linoleum, dissolving the edges of the connected panels and connecting them firmly after cooling. Seam is colorless and almost invisible unless you know where it is located.

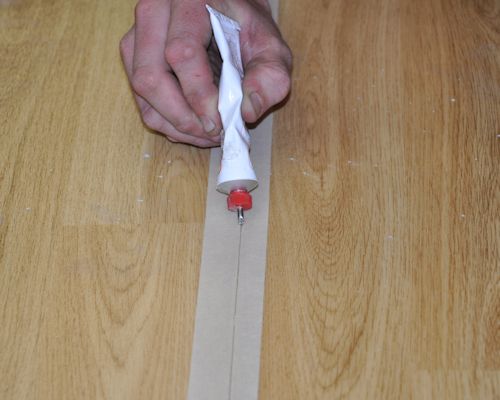

Glue is available in tubes, equipped with special narrow spout through which the composition is applied on the joint.

For cold welding of linoleum is not required special skill, it can be used at independent repair facilities.

Pros and cons of the method

For cold connection method no need to purchase additional equipment. In addition to the adhesive for cold welding of linoleum, you will need a spool of masking tape.

Special skills not required, the job does not take much time, and the result is a virtually invisible seam.

The drawbacks of this method a little bit. These include high toxicity adhesive for cold welding of linoleum, and that method is not recommended when multi-layer material or if at the bottom of padstein sealer. The seam will turn out poorly and very visible.

Types of cold welding

There are three types of composition for cold welding of linoleum. They differ in the consistency and active ingredients that make up the glue. To choose the necessary composition should be based on the width of the future interface.

Type a

This type of glue with a liquid and contains a high percentage of solvent. Mainly used for cold welding of linoleum from PVC (polyvinyl chloride) and with the smallest gaps - a maximum of 1 mm. the Tube, usually has a special narrow nose. On the sides of the weld necessarily is glued to the masking tape to avoid getting glue in unwanted places.

The fact that the composition can "corrode" the surface of the coating, because it is designed for connection at the molecular level. In contact with the glue will leave an indelible stain and, in addition, disrupt the protective layer of material, which in this place will be vulnerable to wear or moisture.

Ideally, if the seams of the linoleum cold welding type And will consist of edges that are cut, not by hand at the factory. This composition can be welded linoleum flooring immediately after laying, not keeping it for a long time. The glue type And cannot be used for welding coatings felts and polyester base.

Type

This type of glue is used when the material is already "Mature"after installation. It is more dense than the composition of type A, the rest of these mixes are identical. The junction of linoleum in cold welding type C may be 2 mm wide or more.

Allowed some roughness of the seam, so the adhesive of this type is often used when you need to connect the old with the new piece in the repair. The mixture is applied to the junction in large numbers and spread, forming an additional protective layer. The tape in this case can not be used.

T

This kind of cold welding for linoleum is used usually by professional workers. Working with glue such as T difficult for the competent use of required skills. Besides, it is more toxic than the compositions of types A and C. the compositions of the type T is designed for gluing of linoleum from polyester or a felt base.

Training interface

The Successful welding of linoleum is possible only with thorough and careful preparation:

- The first thing you need as tightly as possible to fit the pieces of material to each other;

- Then you need to fix the sheets of linoleum on the floor, so they do not slipped during gluing, it is convenient to use double-sided tape;

- Seam area should be vacuumed or wiped with a damp cloth to remove any contaminants;

- On both sides of the joint is glued with masking tape so the glue does not hit anywhere except the seam;

You can then proceed directly to the welding process.

Welding Technology

Apply glue best "one fell swoop", and pieces with a length of approximately two feet. Then will be able to control the thickness of the seam and see that it went smoothly, not off to the side. At hand is better to have a cloth or tissue to quickly wipe off the glue, if it will get uncovered the plot of linoleum.

Bonding of linoleum cold welding is simple: should uniformly maintain the tube along the seam, a little pre-suglobov his nose. However, we need to control the speed that the glue was not enough and the work was not necessary to repeat. Better to glue slightly protrude above the surface after curing, which takes approximately two hours, the excess can be cut off. You can't remove the excess glue before drying - this can lead to disruption of the structure of the seam.

There is another way of gluing of linoleum cold welding composition is applied alternately on both edges of the connected pieces of linoleum, after which they are joined and pressed against each other. This method can be used when gluing small pieces of material or when bundled with a tube is not the needle for accurate application.

As the glue is toxic, care must be taken about the safety of the work. The room must be well ventilated, and work with welding you need to wear gloves, goggles and a respirator.

Repair of old linoleum

Cold welding has been successfully used not only when laying new pavement. If you have already laid the linoleum has been damaged in any way, and replace it did not want to or not, welding will help to restore the surface.

To repair minor damage such as punctures with a diameter of 1-2 mm it is possible to apply the adhesive type A. Damage should tape and cut a hole the right size through which to pour the composition. When making holes needs to be controlled to the edge of the tape didn't get in. After curing, cold welding, remove the tape and level the surface.

If the damage has a large area, you should use composition of type S. In this case, the tape is not required, and the glue actually plays the role of putty. After drying and leveling the surface you can use special mastic for additional masking renovated space.

Foreign manufacturers glue

Cold welding is a popular type of connection of the linoleum, so the shops in the line of both foreign and Russian brands.

From foreign manufacturers it is necessary to highlight the German company Tarkett and WernerMuller. The latter has in its line of cold welding of all three types, and Tarkett is a famous company in the market of building and finishing materials, has long-established high quality.

The Price of adhesive for cold welding of linoleum in Germany - more than 300 rubles for a tube, but it is worth the money. These companies made formulations can be used safely, confident in the result of future work.

From cheap manufacturers of the cold welding, it is possible to mention SINTEX (Spain). The cost of one tube is about two times cheaper than its German counterparts.

Patriotic products

Among Russian brands, the most popular glue RICO. It is made in Saint-Petersburg, its advantage is the absence in one is extremely toxic and complicating storage component tetrahydrofuran, which is in almost allthe compositions of other manufacturers. Is used instead of urethane rubber, giving the coupling high integrity, strength and elasticity. The price for cold welding for linoleum RICO - 200 rubles for a tube.

Another good part of the Russian production - cold welding Homakoll. It is suitable not only for bonding any type of linoleum, but for the tiles of polyvinyl chloride (PVC). The cost of one package is about 250 rubles.

Cold welding "Second" is the most inexpensive option of Russian compositions for bonding of linoleum, its price is about 150 rubles.

Helpful tips

For pre-purification of the joint is not recommended to use solvents or cleaners. They can enter into a chemical reaction with the adhesive composition and to break the connection process.

If the clearance between the webs of linoleum is quite small, the masking tape can not be glued on the sides of the joint. Better to stick directly to it, then making the incision through which to introduce the glue. This minimizes the thickness of the seam and make it less visible.

To the joint to be maximally tight, glue the pieces of linoleum is recommended to impose on each other, to put a marking and to penetrate through. In this case, the seam will be perfectly smooth, but when buying linoleum to lay some stock in this operation.

Article in other languages:

Alin Trodden - author of the article, editor

"Hi, I'm Alin Trodden. I write texts, read books, and look for impressions. And I'm not bad at telling you about it. I am always happy to participate in interesting projects."

Related News

Breed of geese Linda: description, characteristics, cultivation and breeding at home

Breed of geese Linda is considered among the best representatives of the species. To receive were crossed with Chinese and Russian birds with the best characteristics. A very long time, according to one legend, the geese came to t...

The supervisor - who he is, where he came from and why

the Supervisor. Who is this, it becomes clear not at once, as the word for the Russian language new is the borrowing of foreign vocabulary. The meaning of such import foreign words becomes clear as soon as will be able to understa...

How to choose a metal detector: a review of the best models and manufacturers

the answer to the question about how to choose a metal detector for the beginner, can be difficult. There are many different brands and models with the same number of features, options and prices. Read ads in trade magazines doesn...

Young professionals: how to staple the documents

a Large amount of documents available in any organization. Not all of them need the firmware. Beginners to experts, this operation can be completely obscure and unfamiliar. So let's see how to stitch the documents, and why, in Gen...

The content of laying hens in the country and care for them

the Contents of laying hens in the country brings a lot of benefits. As a home egg, its nutritional value is incomparable to the store. There are different breeds of laying hens. Photo relatively easy to find. However, in househol...

The main disease of goslings and their treatment

the Big damage to economy cause of the disease of goslings and their treatment should be conducted in a timely manner. Otherwise, the youngsters will lag behind in development and growth, or there is a risk in General to lose live...

Comments (0)

This article has no comment, be the first!