Kanban - what is it? The principle of lean production

Kanban – what is it? Very interesting information contains the card is Kanban, and how the method performs in the production? In the article, we will explain the rules of effective use of Kanban, and give a vivid description of the circuit use appropriate maps for a specific example. In addition, after reviewing the material you will learn why the need for a Kanban Board, in what areas, in addition to production, it is advisable to apply this method and that can be a good alternative to him.

The essence of the concept and main features of the method

Today we can observe the trend to increase costs of storing inventory, which is the main reason for the formation of complexes “instant” management where is the Kanban system. In Japanese "Kanban" means "tag", "icon". This term serves as a method of informing by which consent is given, or an indication of production or elimination (transfer) of the product pull system.

The report of information allows you to fully manage lean production lines through the use of information cards to transfer a certain order for manufacturing with the subsequent stage to the previous one.

The Developer of such a production system is Toyota Motors, explaining the idea as one of the first attempts of practical implementation of the method “just in time”. In Kanban, the production is carried out in accordance with the following rule: units of the enterprise are supplied with resources in a specific and clearly defined the time required for execution of the order.

Recommended

Staff evaluation: system and methods

Personnel Assessment allows you to identify how competent the employees involved in the enterprise, and it is the performance of their work – the most significant factor affecting the efficiency of the company. To clarify the impact of performa...

How to start your own business: important aspects.

Many people, tired of working for someone else, are increasingly thinking about how to start your own business. Someone wants to open a salon, someone store, and someone enough and vegetable stalls. Before you throw in the pool with his head, it is i...

Business activities. its essence and basic functions

The Entrepreneurial activity of the citizen – is undertaken at your own risk and independent activity, which aims to systematically profit through the sale of works, goods, services, use of the property. The citizen engaged in such activities, ...

Process Details

The Scheme of the presented method is extremely simple, it nevertheless has a very effective effect on the organization of the production process. After the supply units of the company in respect of the resource, carried out a detailed calculation of the required volume of work in progress, which should come directly from the penultimate stage (order of the finished product, respectively, is the final stage of the process). Similarly, with the penultimate stage, a request is made to the previous stage, the specific volume of semi-finished products.

Thus, large-scale production in a particular area is formed in accordance with the needs of the next production stage. Logically, between each two stages of the production process, located next door, is set a double link type:

- N-th stage to n-1 is requested ("pulled") the required amount of work in progress.

- With n-1-th stage to n-th resources go, of a material nature in the right amount.

Tools of information transmission

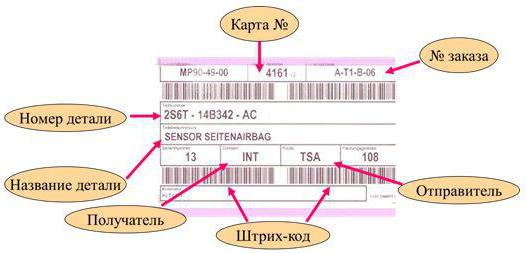

To better understand Kanban - what it is, it should be understood that the instrument of transfer of the information in this system are special cards that are classified into two groups:

- Tools, of direct relevance to the production order. In this kind of cards in the first place indicates the number of parts to be produced at the previous stage of the production process. They go with the n-th stage of production to stage n-1 and are the primary cause for the development of the production program of these sites.

- Screening Tools include information concerning the resources required of a material nature (this can include semi-finished products, materials, parts, etc.) that need to be taken at the previous Assembly stage. This kind of card display resource amount, upon received n-th stage of the production process from n-1-th.

It is Important to note that the cards can make circulation not only in relation to the internal infrastructure of the enterprise, but also between its branches, or corporations that support cooperation.

Effective use of Kanban - what is it?

Taiichi Ohno, President of Toyota Motor Corporation, has developed a number of principles that allow to maximize the use of Kanban

- Follow-up action in relation to production activities shall withdraw the amount of details specified by the card from the previous transaction.

- The operation is in front is in line with the creation of parts in the quantities and sequence specified in the specific card.

- There are No such parts, which can be created without a card. This provision allows for reduction of overproduction, and excess movement of products. Thus, the volume of cards staying in circulation, equivalent to the maximum number of reserves.

- Card – an order for the production of the product (the product in any case is attached to the card).

- Part that has any defect, may not be transferred to the subsequent process. This provision allows you to make an issue of maximally defect-free products.

- Reducing the number of cards increases their level of sensitivity. So, come out the existing problems and implemented effective controlstocks.

Features of the application cards

As it turned out, the management of Kanban is carried out according to a certain scheme, which involves the use of special cards. So, in the course of their application in full must be implemented requirements to ensure absolute visibility and ultimate security of the system: eliminates loss of the card, as well as their mixing.

Experts have developed effective means to give maximum productivity Kanban system. Board this method serves as a gathering place for active cards, because so often in the workplace employees use several different tools. Thus, cards that are to the manufacturer, are placed to the management Board. And when the newly received card tools reach the field “run”, the entire set of cards corresponding to the numbers of parts are transferred for further production process.

The advantages of using the method Kanban - what is it?

The Enterprises applying the system, CANBAN, daily delivery of material resources (and often several times throughout the day). This allows you to fully update inventories of approximately 100-300 times during the year. If you compare Kanban with such systems as MRP or MAP, in this case, is updated approximately 10 times more often.

Suitable for evaluation of the method Kanban examples, revealing his absolute advantage over other, less productive. So, Toyota Motors in one of a plurality of sectors of production in 1976 supplied resources three times a day, and in 1983 - already every ten minutes.

Kanbans are Often used in work with computers (specially formed for this stock). So, the user sends to supermarket Kanban selection, which indicates, as noted above, the volume of the product, and the supermarket gives him a specified number of items. At the same time, the supermarket sends in the direction of a supplier Kanban replenishment, after which the supplier sends the products to the supermarket.

Fundamental elements of method

The most Important components of a Kanban system are as follows:

- Complex Information, which contains in its structure not only cards, but also graphics production, transport or logistical nature, as well as maps technological orientation.

- Complex, which has a direct relation to the control requirements and rotation of personnel in the professional plan.

- Complex, allowing for universal (TQM) and selective ("Jidoka") quality control of the product.

- Complex, provides absolute alignment of the production.

The elements applied together, allow to achieve the shortest production cycle, the high level of turnover of assets (including reserves), as well as to remove or cause the minimum overhead to store both production and inventory and, of course, to achieve the highest product quality at every stage of the production process.

The shortcomings of the system and the results of its application

As with any development, the system “just in time” has some disadvantages. First, it is the complexity of the organization high level of consistency between the stages of production of a product.

The second – a significant risk of disrupting the production process, respectively, and implementation of products. However, a detailed analysis of the global practices in relation to the application of this method showed that the presented system makes it possible to reduce inventories in half, and commodity – 8%, with a significant acceleration of turnover of working capital and, of course, the improved quality of the finished product.

It is Important to note that the use of Kanban is not the end of the production process. Thus, the system is widely used in office and project activities in the programming (there are a range of kanban development), but also in achieving personal results (personal Kanban type).

Article in other languages:

HI: https://www.tostpost.com/hi/business/23560-kanban.html

KK: https://www.tostpost.com/kk/biznes/39838-kanban---b-l-ne-princip-ypty-nd-r-s.html

PL: https://www.tostpost.com/pl/biznes/41592-kanban---co-to-jest-zasady-lean-manufacturing.html

PT: https://www.tostpost.com/pt/neg-cios/41235-kanban---o-que-o-princ-pio-da-produ-o-enxuta.html

TR: https://www.tostpost.com/tr/business/36399-kanban-nedir-yal-n-retim-prensibi.html

Alin Trodden - author of the article, editor

"Hi, I'm Alin Trodden. I write texts, read books, and look for impressions. And I'm not bad at telling you about it. I am always happy to participate in interesting projects."

Related News

for a long time all over the world used convenient way to move goods. Currently, there are a large number of different capacities for transportation, small and large. Types of containers, as they are called, are different, they ar...

Staffing - what is it? The standard and calculation of the number of staff

optimization of the structure of human resources of the enterprise may require its responsible managers to perform significant work connected with the determination of staff number of staff. What is this indicator? How is it deter...

In any case the most important thing – the right way to start. This assertion is quite true for the currently popular project management. Where do you start? What is the concept of the project? Examples and the theoretical b...

"Varyag" - the aircraft carrier. Description, characteristics, photos

Carriers – majestic court, which symbolize the military power of the state. Today we'll meet the heavy aircraft-carrying cruiser “Varyag”, which was quite interesting and confusing. The ship was created in the US...

Cable manhole: design features, functions, models and sizes

Cable well today found wide circulation. It is widely used in the process of construction and, if necessary, laying of cable systems. To classify these products is possible in two ways. The first kind is designed for conduit conne...

"Motivators": employee reviews, addresses of shops, flower delivery

Today, we must understand what "Motivators" feedback staff receives. And anyway, what is this organization, what services and rates it offers. All this is extremely important for those who want to cooperate with the employer. What...

Comments (0)

This article has no comment, be the first!